Reaming is often a machining system whereby a multi-toothed fluted tool enters an existing gap to really make it larger. The outcome has an exceptionally easy surface end with tight engineering tolerances. The operation alone seems just like drilling from the outset.

No matter your venture or content, no matter if it’s metal or plastic, our CNC machines empower you to definitely convey your Inventive visions to everyday living

CNC lathes rotate spin the workpiece in the spindle (rather then the mill tool head in mills), with a set slicing tool slicing chips from the spinning portion.

This machine is as difficult and durable because it will get for a little cnc lathe, making it perfect for precision production Positions for example aerospace parts.

Versatility: CNC turning can take care of several supplies, rendering it suitable for several industries and applications. CNC turning centers present advanced capabilities further than easy turning functions, which include milling and drilling.

A twelve slotted tool turret will provide you with the entire flexibility and tooling abilities you'd probably count on from a much larger machine. There exists a good deal to like concerning this smaller workhorse lathe and it truly is backed by a brand identify you may have confidence in.

On the subject of uniformity and compatibility, it may be clever to use the same brand title machines. It can help you save revenue when getting your tooling or when getting a company rep to come in and do routine maintenance.

Something to remember just before selecting a less costly compact CNC lathe alternative is the fact that “limited budgets” don’t usually do the job with “tight tolerances”.

A CNC lathe is undoubtedly an assembly of intricate components, each taking part in a vital role in its Procedure. Comprehension these components gives you a deeper insight into how these machines reach these kinds of high amounts of precision and efficiency. Right here’s a breakdown of The crucial element parts:

ABS Plastic: ABS is often a hardy, influence-resistant plastic that machines very well, which makes it a fantastic option for tough parts and prototypes.

Eliminating any remaining burrs or sharp edges from the machined surfaces using deburring tools or procedures.

Some non-ferrous metals have decrease hardness and higher plasticity, that may result in gentle debris to clog grinding wheels and allow it to be challenging to reach a sleek surface area with grinding. Hence, grinding is not really ideal for these resources. Any time a reduced area roughness benefit Discover is necessary for non-ferrous metallic parts, turning or milling is desired for precision machining.

The key distinction lies while in the movement with the workpiece, with CNC turning excelling in developing cylindrical parts and CNC milling featuring a broader choice of possibilities for complex geometries.

Use “Relative ON” to enter a particular coordinate to jog any of one's axes to a precise area without being forced to compose a system. It’s like employing “power feed” but less complicated.

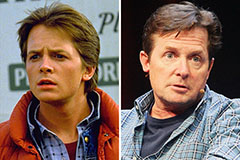

Michael J. Fox Then & Now!

Michael J. Fox Then & Now! Sam Woods Then & Now!

Sam Woods Then & Now! Monica Lewinsky Then & Now!

Monica Lewinsky Then & Now! Tyra Banks Then & Now!

Tyra Banks Then & Now! Tonya Harding Then & Now!

Tonya Harding Then & Now!